Our Technology

Key Benefits:

- Lower temperature via the Catalytic Process: Our proprietary catalyst permits our Plastic-to-Fuel process to conduct at lower temperatures than competitors.

- Higher Yields: Our catalytic process produces yields at greater than 80%, which represents a 25% increase in yields from our competitors

- Consumption-Ready Fuel: The primary output of our process is diesel or gasoline that is ready for use in engines. No need to refine!

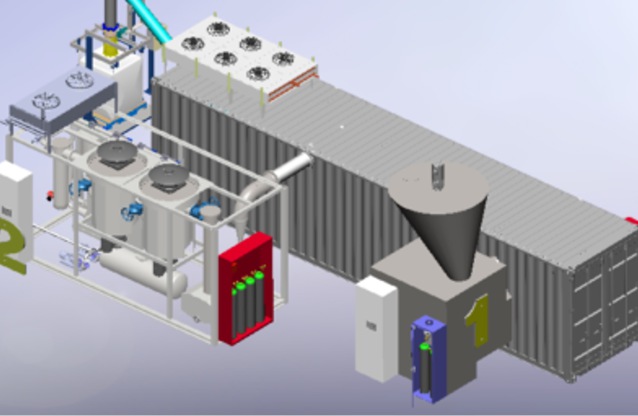

Technology Overview:

Plastics (specifically codes 2, 4, 5, and 6) can be depolymerized into useable products using heat in the presence of catalysts developed by the EFT. While other similar processes typically achieve this using much higher temperatures, EFT’s low temperature (350°C - 450°C) catalytic process converts plastics to fuel at a lower cost and with yields greater than 80%.

EFT's proprietary nano-engineered catalysts and technology enable gasoline, diesel, or lubricating fluids to be produced as an end product with no additional refining necessary. (By contrast, comparable U.S.-based technologies generate only crude oil.) The only byproducts are the EFT technology are gases, which can be burned to supply the needed heat, and about 5% char, which studies have shown can be disposed of safely in landfills.

EFT’s technology will tolerate impurities to a certain extent and process commingled plastic. For customers, this means:

- There is no need to separate different plastic types.

- These is no need to clean the source plastics extensively.

- Preparation and set-up is minimized.

- Costs and resourse requirements are reduced.